Real Graphics

-

Squidmob567

- Posts: 289

- Joined: Thu Jun 04, 2015 12:25 am

- Team: BGFX

- Location: Michigan

- Contact:

Re: Real Graphics

Our Timbersled template fits like a puzzle first go. Stoked on how this setup came out for this guy.

Re: Real Graphics

Excited to get this printed.

-

On The Pipe

- Posts: 1350

- Joined: Mon Mar 15, 2010 2:51 am

- Team: Factory Suzuki

Re: Real Graphics

What is your guys preferred method for installing graphics?

Dry or Wet, If you go wet you used windex or soap? Do you need a heatgun/hair dryer if you apply wet?

When installing new seat foam to plastic base is there any reason to use adhesive?

Dry or Wet, If you go wet you used windex or soap? Do you need a heatgun/hair dryer if you apply wet?

When installing new seat foam to plastic base is there any reason to use adhesive?

-

Racing299

- Posts: 255

- Joined: Sun Jun 08, 2014 5:59 pm

- Team: Flex Factory Racing

- Location: New Jersey

- Contact:

Re: Real Graphics

I just install graphics dry with a heatgun, and Ive never done seat foam but I have done covers. I would think a little glue or something, maybe just staples, to keep it from sliding around under the cover. For covers, I just use staples, and quite a bit of them.On The Pipe wrote:What is your guys preferred method for installing graphics?

Dry or Wet, If you go wet you used windex or soap? Do you need a heatgun/hair dryer if you apply wet?

When installing new seat foam to plastic base is there any reason to use adhesive?

dbaum25moto wrote:That horn is the greatest technological achievement by any manufacturer in the history of offroad motorcycling. My bike is super quiet, allowing me to sneak up behind my friends and scare the shit out of them.MaicoBreako wrote:Plus it has a horn.

-

Ohagan75

- Posts: 3777

- Joined: Mon Jan 23, 2012 3:17 am

- Team: Prime Design GFX

- Location: Australia

- Contact:

Re: Real Graphics

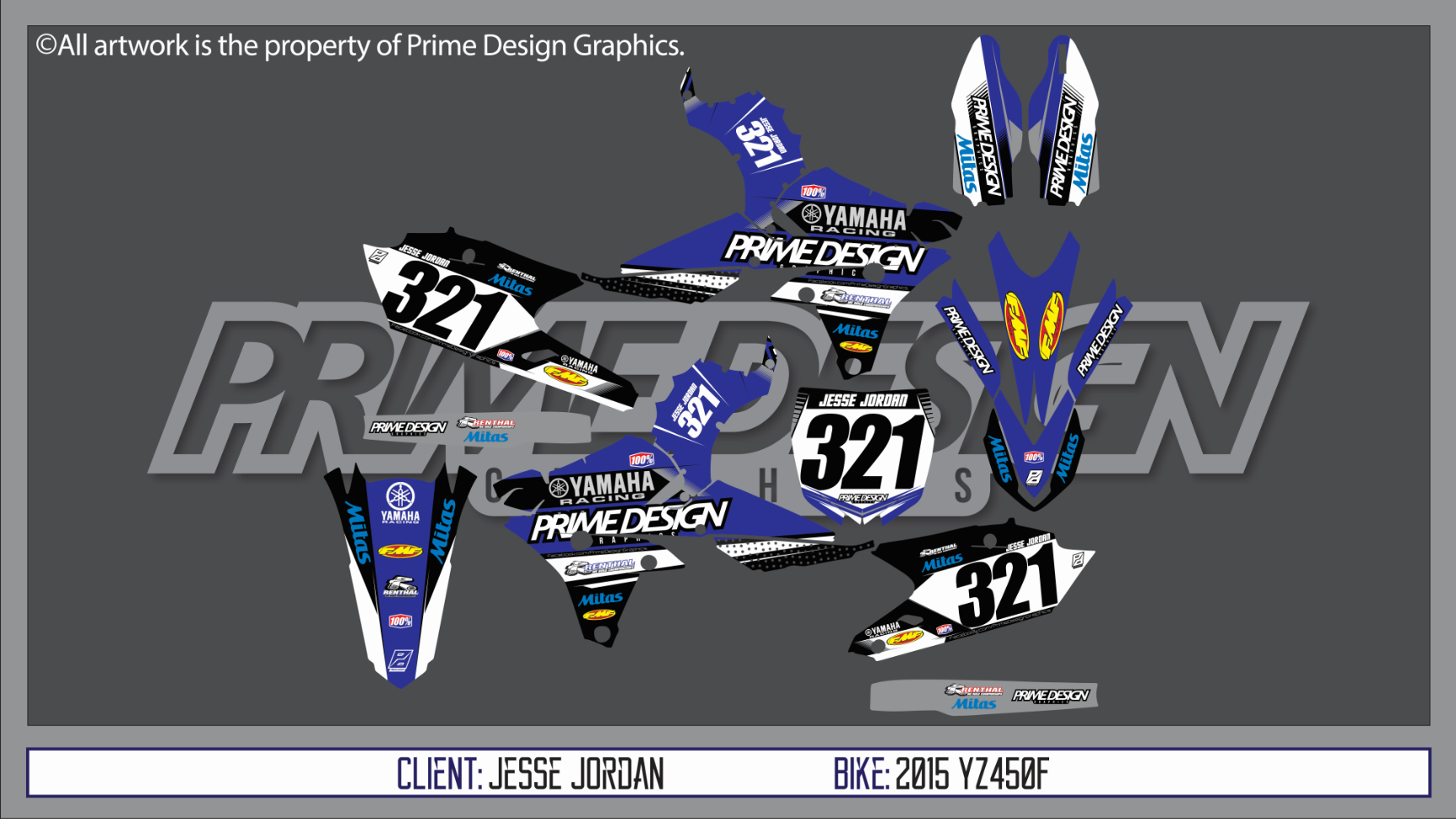

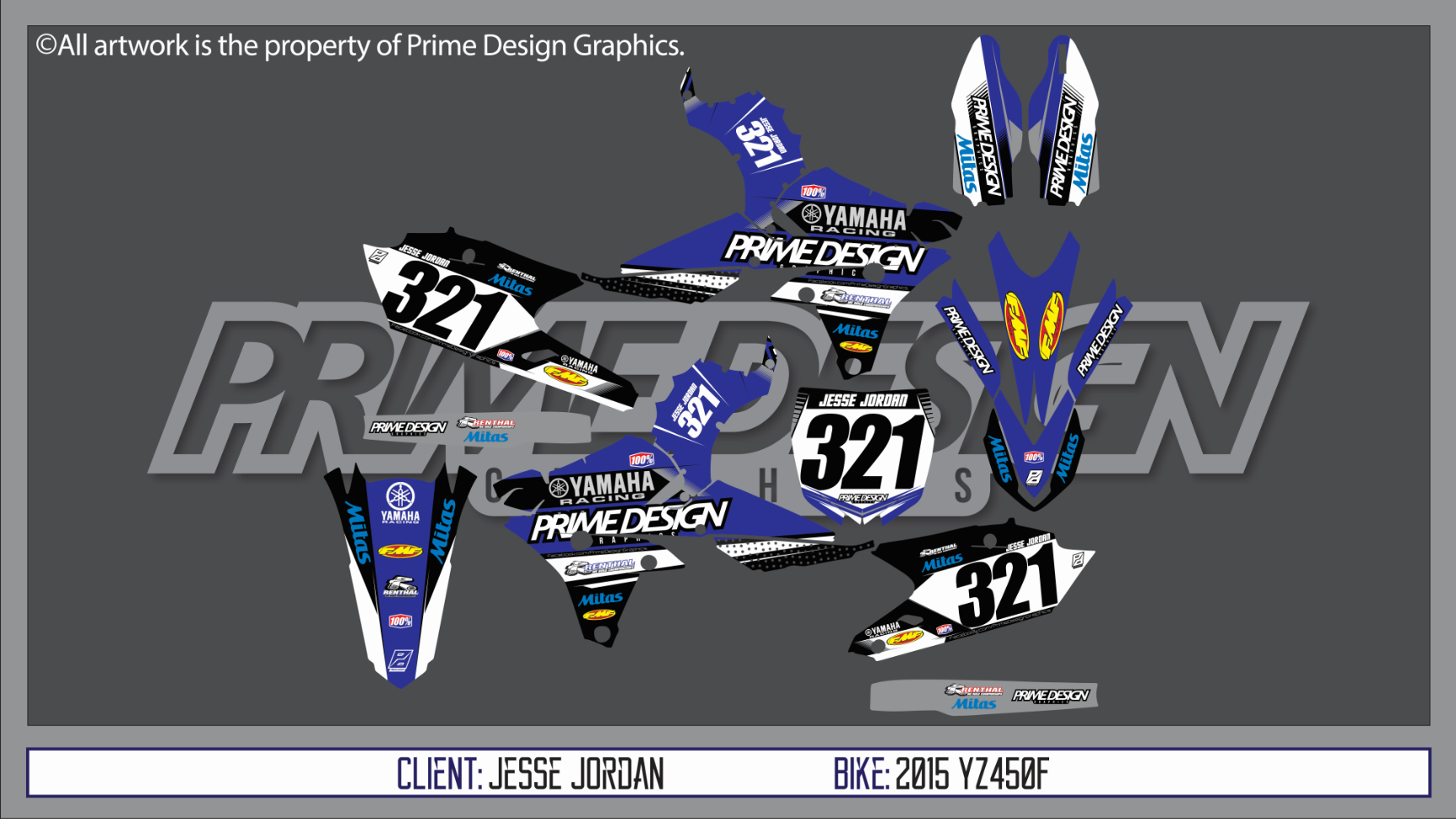

some more kits i've done recently

did these a while ago but he just got his 125 sorted.

did these a while ago but he just got his 125 sorted.

-

Squidmob567

- Posts: 289

- Joined: Thu Jun 04, 2015 12:25 am

- Team: BGFX

- Location: Michigan

- Contact:

-

Squidmob567

- Posts: 289

- Joined: Thu Jun 04, 2015 12:25 am

- Team: BGFX

- Location: Michigan

- Contact:

-

Squidmob567

- Posts: 289

- Joined: Thu Jun 04, 2015 12:25 am

- Team: BGFX

- Location: Michigan

- Contact:

-

mikehunt22

- Posts: 266

- Joined: Sun Dec 08, 2013 1:17 pm

- Team: Privateer

- Location: Southern England, UK

Re: Real Graphics

thought id ask as some of you guys own the equipment, but what machines and supplies are needed to print and make graphics? because i see that its quite a large setup.

-

Ohagan75

- Posts: 3777

- Joined: Mon Jan 23, 2012 3:17 am

- Team: Prime Design GFX

- Location: Australia

- Contact:

Re: Real Graphics

It's quite an investment if you're just getting started making graphics. If you have a spare 15k to drop on printing equipment, then by all means go ahead, but maybe I would recommend using a third party for printing for at least a year or two just so that you can build up a client base.mikehunt22 wrote:thought id ask as some of you guys own the equipment, but what machines and supplies are needed to print and make graphics? because i see that its quite a large setup.

-

mikehunt22

- Posts: 266

- Joined: Sun Dec 08, 2013 1:17 pm

- Team: Privateer

- Location: Southern England, UK

Re: Real Graphics

wow that's incredible, one hell of investment. I was just interested after seeing that vid fammx put out showing some of the graphics process.Ohagan75 wrote:It's quite an investment if you're just getting started making graphics. If you have a spare 15k to drop on printing equipment, then by all means go ahead, but maybe I would recommend using a third party for printing for at least a year or two just so that you can build up a client base.mikehunt22 wrote:thought id ask as some of you guys own the equipment, but what machines and supplies are needed to print and make graphics? because i see that its quite a large setup.

-

mxr449

- Posts: 584

- Joined: Tue Jan 24, 2012 5:43 pm

- Team: SYS / FAMmx Design

- Location: Quad Cities Illinois

- Contact:

Re: Real Graphics

I had a lot of trouble finding any information on this topic when I was starting out so I thought I would reply and give you my advice and tell you a bit of what I learned when getting involved with this. I tried my best to answer your question about the equipment that is required as well as some of the other things that is involved with starting up your own business. Sorry it's a bit longer than I intended.mikehunt22 wrote:thought id ask as some of you guys own the equipment, but what machines and supplies are needed to print and make graphics? because i see that its quite a large setup.

It's definitely a huge investment and there is a lot more that goes into it than what most people think. When I first decided I wanted to make motocross graphics, I thought all you had to do was design and press print and I was completely wrong. After college, I began doing design, production and marketing work for a Sign Shop in the Quad Cities. That was a great way for me to learn what all goes into it without having that difficult of jobs to complete.

It is very hard to start a motocross graphics company and be successful. There are too many other MX graphic companies to compete with and to be honest, without Mx Simulator, i'm not sure if this is the route I would of took.

I've been fortunate to have met many of you guys in the Sim Community that have brought me business and I couldn't be more thankful. This has helped me get graphic kits sent out to many different states and countries. Also, I do a lot of work for Amsoil Arenacross because a few of their employees that travel to each round live in my area. Both last year and this year they had me do all of the transponder, radio and headset decals for the entire series. Without the community and arenacross, I'm not sure if I would have sold any graphics outside of my state.

One thing that people told me as I was putting everything together is that If you come into the idea and think you are only going to make Motocross graphics and nothing else, you will never make it. That couldn't be more true and in reality, until you are able to hire employees and have multiple printers, it's going to be hard to find enough time to make nothing but motocross graphics and ignore all other possible work that comes your way. Motocross graphics take a long time to make, even if you have semi custom graphics that are already made. Lets say my semi custom graphics are made for a 2015 Yamaha but you order that kit for a 2005 Yamaha. It may not transfer over as easily as you think because the templates are so much different. You are basically constantly redesigning your already designed kits. Then you have to place the customers desired logos, recreate any logos that you cannot find in vector, send a proof, make changes etc. Also, color schemes can be tricky. If you display a semi custom set with 3 colors, Red, Black and White and a customer chooses Pink, Green and Blue you have to somehow make that look good. That might mean adding in black accents to separate 2 colors that don't have a good contrast or whatever else you may think of at that time. After a proof is approved, you have to set it up to print, print the graphics, laminate them, cut them, package them and ship, for approximately, $200.00.

To be honest, like I said above, you will need employees and multiple printers to be able to fit enough MX graphic orders into your schedule to bring enough money in. Fortunately, every local business in your town needs a designer to make a sign, logo, flyer or whatever else to promote and advertise their product or business. Most of these jobs wont take near as much time as it takes to make motocross graphics and often times costs the same or more for the customer. For example, we do work for a local car dealership. They wanted 1,000 stickers at 13" x 5" that said "Advertised Special" on their cars. By looking at the picture below you can see that most of the people in Mx Simulator could make that in 2 minutes. There is still the production side of things but it's more of a waiting game rather than you sitting there designing one or two kits all day.

With all that being said, here are some of the things to think about when trying to start a graphics company.

Printer Cost: $15,000 + (Depending on the size and unless you are buying a Latex Printer which is around $55,000+ but shows little to no difference than an eco solvent printers. You can find many articles online comparing the two.)

*Note: I do not recommend buying a used printer. We did this and ended up putting a bunch of money into it to get it running again and it never worked well with us. There are so many things that can go wrong with a printer that are stupid expensive. We replaced a capping station assembly which is a small plastic piece about half the size of a business card with tubes coming out for $200. Print Heads are $2,000. Some printers have more than one head, and you get the idea. If someone is selling a printer, it's probably been sitting around for a long time meaning that all the ink has dried up in the lines, head, capping station and in other parts of the machine.

When buying a printer, there are a couple things to consider. You can get a 30" printer that will do motocross graphics just fine for about $15,000 however, many people will want things much larger such as signage or banners. For an additional $5,000 - $20,000 you can get nearly twice the size. This will allow you to be able to produce many different types of signage or displays that would otherwise be difficult or impossible to make with a 30".

Also, 30" is coming real close to being too small for some of the template pieces for newer bikes and 30" doesn't mean you can print the entire width of 30". By the time you add in crop marks, set up your pinch rollers to advance the media through the printer, it's more like 25" - 27". Having a 30" printer means that you cant set too many things side by side in a print and this doesn't work well with the plotter, unless you have a flatbed plotter which is much more expensive. I'm not sure why but with every plotter that i've worked with, it can be hard for it to accurately read the crop marks, which is how it determines where to cut, on pieces that are longer than about 6-8 feet. If you had a 30" printer, you would probably find yourself printing nearly each piece by itself which then means you would have to cut each one by itself as well.

Laminator Cost: $8,000 - + (For a heat assist motorized laminatorand and depending on what size)

You could laminate by hand but that will make things very tough and you will probably find weird bubbles and lines because you aren't able to accurately apply pressure throughout the entire width of the material and you can't keep a constant speed. If you use a manual laminator, you will also find lines and bubbles because when laminating, you need to keep a constant speed without slowing down or speeding up.

Plotter: $4,000 + (Depending on what size)

This is what cuts out the graphics after they are printed. You will need to make sure the plotter you are getting will cut through Motocross Vinyl/Laminate. Motocross graphics are very unique and you don't find many other jobs that require that thick of material. Most of the time, sign shops are cutting at an absolute maximum of 6mil material, unless it is floor graphics or something of that nature. You also need different blades for thicker material. The cheap plotters you see from china will not work very well. You will be lucky to cut even halfway through the material and you will also have blade dragging problems while the plotter is in motion - which will result in scratch marks on your graphics. We use 2 different plotters, one for motocross, and one for other types of material.

Rip and Print Software: $2,000+ (Unless your printer comes with one)

Not all printers print the same and it's important to make sure the colors shown on your screen are close to what will come out of the printer. TV Screens, Monitors, Cell Phones, etc. use RGB Color and Printers use CMYK. You won't be able to match the colors on your screen exactly with or without a Rip and Print software but with a good software you can come very close. Also, different vinyls require different settings on the printer. A vinyl material that is made for vehicle wrap might require a higher temperature setting, different levels of ink distributed, etc. With a Rip and Print software, you can contact nearly any vinyl supplier and have them send you the appropriate profile for a specific product. This way, you will have the most vibrant and even colors possible when printing on different types of vinyl. You can also make your own printer profiles and much more with a Rip and Print software but many of the features that come in these programs you wont use and unfortunately, this doesn't bring down the cost.

A few other costs and headaches are

Maintaining the equipment.

If you don't use the printer everyday, or even once a week, you will start to see missing nozzles in your test print. If this gets bad enough, you will need a new print head that will cost around $2,000. Some printers have more than one head too. You will need to make sure you run clean cycles, hand cleaning and whatever else your printer requires.

Knowing what type of material you need for various projects.

There are two types of vinyl, Calendared or Cast. Ever tried to peel off an old sticker that cracks and is a pain in the ass? Most likely it is calendared vinyl. Cast is more expensive but lasts much longer. You will have to do some research to help you decide which type of vinyl is better to be used for various projects. Within those two categories, there are literally thousands of different kinds of vinyl. Some are made for vehicles, others for signage, temporary use, etc. The type of vinyl you use depends on where the decal will be applied. Some vinyl is good for conforming to curves while others isn't. Also adhesive varies from vinyl to vinyl. If you were to use permanent vinyl on a vehicle, the chances are when you go to peel the wrap off, some paint might be coming with it. They even have repositional vinyl that you can stick, peel up and stick again. You will have to research and know the different types of vinyl. The same goes for laminates. Laminates have a variety of appearances and uses just like Vinyl.

Things you will have to figure out

Becoming a Business

- You will need to go through the appropriate steps for your state to receive your business license and receive a Tax ID number.

- Hire a billing person or learn how to do it yourself.

- Hiring a Lawyer to make sure you are doing everything right

- You have to submit taxes every month and at the end of the year.

- Determing how much tax you received and pay it back to the state each month.

- Calculate the approximate cost of each product you are going to sell.

- Setting product prices for each product that you offer.

Setting up Workshop

- You will need Large tables, rulers, exacto blades, and other necessary equipment that will be used everyday.

- You will need a building or large enough space to put everything in.

- Setting up a sign or something to show the public where you are located.

- Having the right equipment to finish the production of banners, signs, application, etc.

Becoming a Business Online

- Going through Google business to get your business on google maps.

- Setting up Social Media Accounts

- Building a website.

- Having a functioning store that accurately calculates taxes and shipping depending on customer location.

Maintaining a Website:

- Build an entire store from the ground up and having enough products to offer customers.

- Adding new products to your store

- Finding Website Store Software and setting it up correctly.

- Keep track of orders and customers.

Marketing

- Use social media to attract new clients.

- What events could you attend that could possibly attract more customers?

- Is there any event that you can sponsor or be a part of an event or charity to help get your name out?

- Figuring out what other forms of marketing that you want to use.

Packaging

- Where are you going to get the packages?

- What is the largest product you will need to ship?

- What size packages do you need?

- Do you need more than one size?

- What is the cost of packaging

Production/Shipping

- How are you going to add the cost of packaging into your shipping.

- How long does it take to package an item?

- How are you going to determine shipping cost?

- How much is it going to cost you to ship for the various package sizes?

- Which service are you going to use to ship your products?

- Are you going to offer various shipping options like overnight, next day air, etc.

_______________________________________________

And thats pretty much all I can think of off the top of my head but there are definitely more things involved that I can't think of right now. Everything listed above is what we did before we opened. We did everything 100% by the book because we decided we are going to make this an official business, quit our jobs and work at this full time. If you are not wanting to do this full time, there are many things that you may not have to do or worry about. Either way, it is rewarding in the end but it can be a lot of work trying to figure everything out. I will be happy to help as best I can if you have any questions.