I have been working for awhile on trying to calculate torque given rpm, adding force bla bla. Essentially, I am coding an engine, a motor that is, not a game engine.

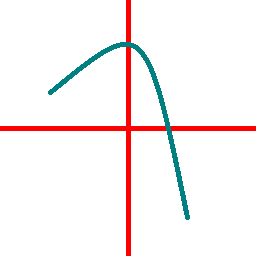

I want to ensure my logic is correct here, maybe someone here could help me out or give their input. I understand that the torque from an engine on a dyno is the torque that is produced at the crank, in other words, in the image below, that Max torque of 30.87 Lb foot is the torque that the engine produces at the crank.

Now my next step is to think alright well the drive goes through gearing with in gear one I have calculated is 1:32 for a '14 Crf250r. Hence, the crank does 32 rotations for even 1 rotation of the rear wheel, meaning the torque will be 32 times as high at the rear wheel as the crank. Which yields, 30.87lbft * 1:32 = 987.84lbft. I convert this to Nm so my head doesn't explode, which results in 1340Nm. Now my logic makes me think that if I was to apply 1340N at 1m from the center of rotation of the rear wheel, I should get correct performance, assuming full throttle.

I am aware im using gearing of a 250 and torque of a 450, but that's not my concern now, I am trying to figure out if my logic is correct.

New next step, RPM.

What is proving to be a challenge, is the fact that the engine increases its rpm by adding air which adds fuel which raises the rpm, but it also goes the other way round, the wheel affects the engine, such as dropping the clutch in 5th gear on idle will almost certainly make the engine stall from the sudden drop in rpm due to insufficient torque. I am wondering, how can I calculate this whole rpm system, especially incorporating a clutch. At the moment I have the following.

RPM = WheelAngularVelocity * (1 / GearRatio)

AngularForceOnWheel (Nm) = Torque@RPM * Gear

The force increases the wheel speed which in turn increases the rpm and hence the system works, the problem is tho, its like constantly being in gear. And incorporating a clutch and achieving a natural idle for example is driving me insane. Any input will be appreciated!

Cheers guys!